The Sudarsan advantage

The printing process for each market or product has its own unique set of requirements in terms of performance and compliance. We are invested to help set your products apart in the marketplace through our technology and skilled people. Our commitment to be always innovative, positions Sudarsan Graphics Pvt. Ltd. as one of the nation’s premium printers.

Complete in house digital to plate process

Advanced offset and digital printing technologies

Specialised finishing for creative marketing applications.

Centrally located for quick logistical support.

Well established quality control.

Skilled employee mindset to ensure continuity in production.

Prepress: Design to Print

The complete prepress workflow is bundled around our computer to plate making system. Ranging from processing tools such as PREPS to automated machine learning curves using PRINTFLOW a lossless transfer of image all the way to our presses are implemented.

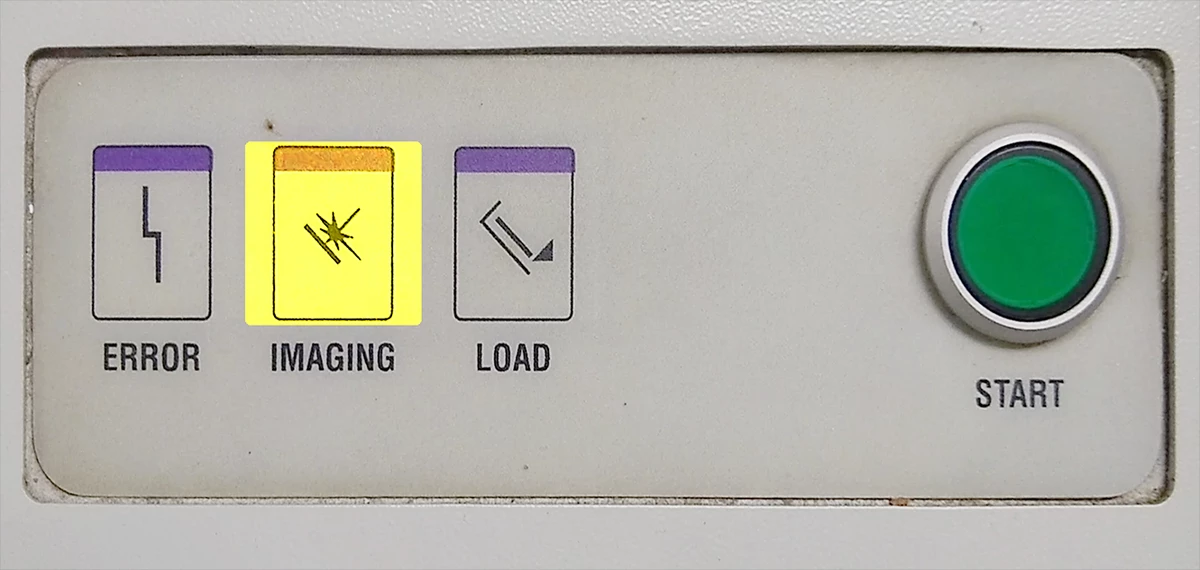

Computer to Plate

The versatile computer to plate system capable of imaging wide formats up to 84 cm x 115 cm. With a maximum resolution of 2400 dpi the machine is capable of producing anywhere between 26 and 30 plates in an hour. This becomes our backbone in managing variable job volumes with the least turnaround times

Photo Enhance

With an array of prepress software at our disposal, a perfect translation to high quality print can be achieved. We assist designers with our experience in formatting their designs to fit the print specifications. Photographs taken even in diffused lights can be enhanced to be vibrant and sharp with our tools.

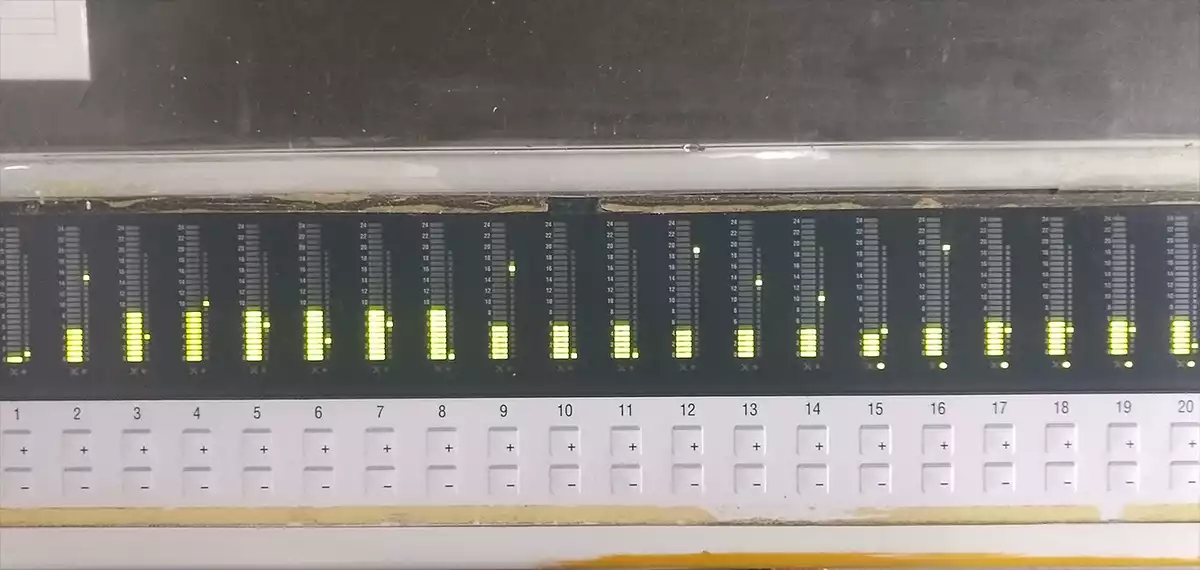

Color Control

Our presses are calibrated based on International colour control to accurately reproduce the colours in Realtime. The press conditions and consumables are profiled and calibrated and the same are uploaded at the prepress to ensure colour uniformity across all platforms.

Total Quality Management

The PRINTFLOW colour control transmits the processed prepress data over to our machines. The ink dosage and set limits are automatically transmitted to the press from the prepress data. Furthermore using a densitometer the printed sheets can be evaluated and corrections are applied in real-time automatically.

Customizied Printing Options

Foiling

A foil film is applied to the print medium to enhance the visibility and makes your product stand out uniquely.

Drip‐off

An alternate high gloss and Matte finish applied to the printed surface as an eye‐catching method to achieve repellent effects in a single process.

Die Cutting

A cutting die pressures over the printed sheet to give the product a unique trim. Shapes are fully customized to enhance aesthetic appeal.

Perforation

A line of tiny holes/cuts is punched into the substrate to enable sheets to be folded, torn off or separated easily.

Varnish

An overall high gloss or Matte finish applied to the printed surface to protect the print from scratching and scuffing as well as add aesthetic appeal.

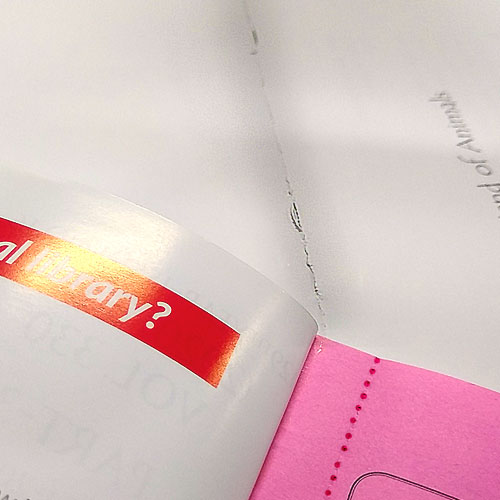

Embossing / Debossing

The design on a print area is raised to give a sensation of depth. Using state of the art laser dies high aspect ratios can be achieved, giving products a premium feel.

SpotUV

Using precise screen‐printing a specific design or a spot is given a contrast through varying levels of sheen and texture.

Security

By adding variable data in the form of QR codes, Holograms and special watermarks makes product appeal more authentic to customers.

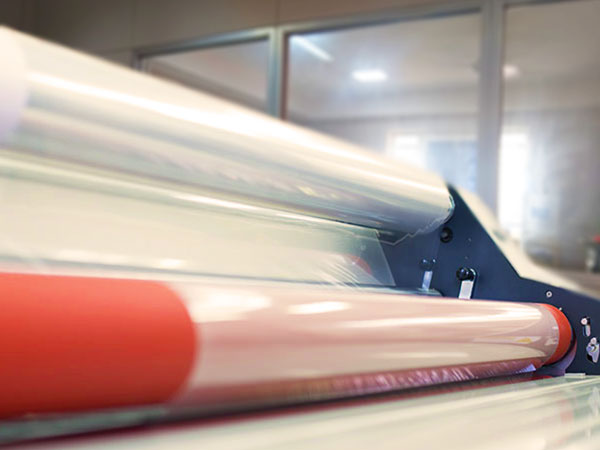

PostPress

Saddle Stitching

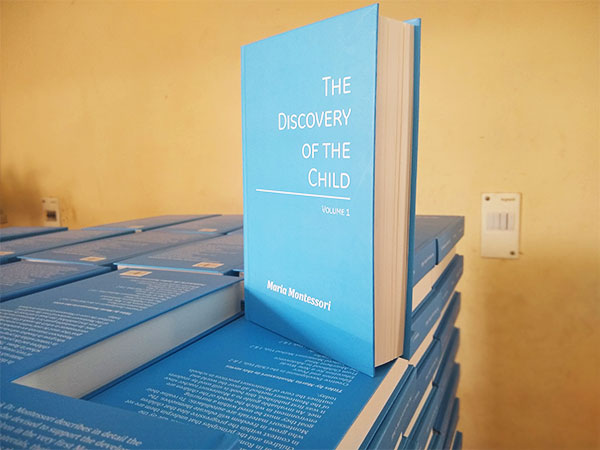

Perfect Binding

Section Sewing

Hard Case Binding

Round Edge and Rounded Back